Unlock the Secrets of CNC Systems: A Comprehensive Guide for Advanced Manufacturing

In today's rapidly evolving manufacturing landscape, the adoption of Computer Numerical Control (CNC) systems has become essential for businesses seeking to achieve efficiency, precision, and productivity. CNC systems offer an unparalleled level of control over manufacturing processes, enabling the production of complex parts with unmatched accuracy and repeatability.

5 out of 5

| Language | : | English |

| File size | : | 10454 KB |

| Text-to-Speech | : | Enabled |

| Print length | : | 476 pages |

This comprehensive article aims to introduce you to the fascinating world of CNC systems. We will delve into the core principles, design methodologies, and practical applications of CNC technology in advanced manufacturing. By the end of this article, you will possess a solid understanding of CNC systems and their transformative role in modern manufacturing.

What is a CNC System?

A CNC system is an advanced computer-controlled system that automates the operation and movement of machine tools. It consists of three primary components: a computer, a controller, and a machine tool. The computer provides the instructions for the controller, which in turn directs the machine tool to perform various operations.

Unlike traditional manual machining methods, CNC systems eliminate the need for human intervention during the manufacturing process. The computer program dictates every aspect of the operation, ensuring consistent and precise results. This level of automation significantly reduces human error and improves overall efficiency.

Types of CNC Systems

CNC systems come in various types, each tailored to specific applications and manufacturing requirements. Some of the most common types include:

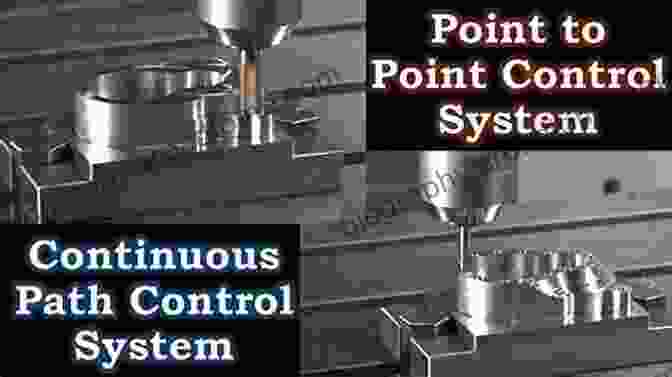

Point-to-Point (PTP) Systems:

PTP systems are designed for applications where the machine tool needs to move from one fixed point to another quickly and precisely. These systems are ideal for drilling, punching, and engraving operations.

Continuous-Path (CP) Systems:

CP systems are used for applications where the machine tool must follow a continuous path, such as contour cutting and milling. These systems offer greater precision and smoother surface finishes than PTP systems.

Robotic CNC Systems:

Robotic CNC systems combine the flexibility and reach of robotic arms with the precision and control of CNC systems. These systems are highly versatile and can perform a wide range of operations, including welding, assembly, and material handling.

Design of CNC Systems

The design of CNC systems involves the integration of several key elements:

Computer Hardware:

The computer hardware serves as the central processing unit of the CNC system. It executes the program instructions and communicates with the controller and machine tool.

Controller:

The controller is the intermediary between the computer and the machine tool. It interprets the program instructions and generates the necessary electrical signals to drive the motors and other actuators.

Machine Tool:

The machine tool is the physical apparatus that performs the actual machining operations. It consists of various components, including the spindle, axes of motion, and cutting tools.

Software:

CNC software plays a crucial role in the design and operation of CNC systems. It includes programs for computer-aided design (CAD),computer-aided manufacturing (CAM),and CNC programming.

Applications of CNC Systems in Advanced Manufacturing

The adoption of CNC systems has revolutionized advanced manufacturing across various industries, including:

Aerospace:

CNC systems are indispensable in the production of complex aircraft components, ensuring the precision and accuracy required for flight safety.

Automotive:

CNC systems automate the manufacturing processes of automotive parts, resulting in reduced production time and improved quality.

Medical:

CNC technology is used in the production of medical devices and implants, where precision and reliability are paramount.

Electronics:

CNC systems play a vital role in the fabrication of electronic components, such as printed circuit boards and semiconductor chips.

Benefits of Using CNC Systems

The implementation of CNC systems in advanced manufacturing offers numerous benefits, including:

Increased Productivity:

Automated operations and reduced cycle times lead to significant productivity gains.

Enhanced Precision and Accuracy:

CNC systems eliminate human error, resulting in precise and consistent machining results.

Improved Quality:

Automated processes ensure consistent quality and reduce the risk of defects.

Reduced Labor Costs:

Automation reduces the need for manual labor, lowering overall manufacturing costs.

Flexibility and Versatility:

CNC systems can be reprogrammed to produce different parts, providing flexibility and adaptability to changing production requirements.

CNC systems are the driving force behind advanced manufacturing, offering unparalleled precision, productivity, and efficiency. By mastering the principles and applications of CNC technology, businesses can unlock their full manufacturing potential and achieve competitive advantage in today's global marketplace.

This comprehensive guide has provided a thorough to the world of CNC systems. Whether you are an engineer, manufacturer, or simply curious about the latest manufacturing technologies, we hope this article has shed light on the transformative capabilities of CNC systems.

For further in-depth knowledge and practical insights, we highly recommend the book "Theory and Design of CNC Systems" by Springer. This acclaimed publication delves into the intricacies of CNC system design, analysis, and implementation. By studying this book, you can expand your understanding and become an expert in the field of CNC technology.

5 out of 5

| Language | : | English |

| File size | : | 10454 KB |

| Text-to-Speech | : | Enabled |

| Print length | : | 476 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Greg Aunapu

Greg Aunapu Cameron Ferguson

Cameron Ferguson John Beaulieu

John Beaulieu Constro Facilitator

Constro Facilitator George Lizos

George Lizos Phil Willmot

Phil Willmot Marc Weissbluth M D

Marc Weissbluth M D Shifra Horn

Shifra Horn Janet O Carroll

Janet O Carroll Sally Morgan

Sally Morgan Jason R Rich

Jason R Rich Angela Dunbar

Angela Dunbar John Doezen

John Doezen Valentina Giannella

Valentina Giannella Nathan Ameye

Nathan Ameye Tanushree Podder

Tanushree Podder Mike Rutherford

Mike Rutherford Philip Rastocny

Philip Rastocny Carina Heckert

Carina Heckert Susan A Berger

Susan A Berger

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

John GrishamUnlocking the Secrets of Mental Health: Your Comprehensive Guide to Symptom...

John GrishamUnlocking the Secrets of Mental Health: Your Comprehensive Guide to Symptom...

Michael SimmonsUncover the Secrets of Life at the Molecular Level: Molecular Biology of...

Michael SimmonsUncover the Secrets of Life at the Molecular Level: Molecular Biology of...

Henry Wadsworth LongfellowManaging the Menopause: A Comprehensive Guide to Navigating This...

Henry Wadsworth LongfellowManaging the Menopause: A Comprehensive Guide to Navigating This... Stephen FosterFollow ·3.7k

Stephen FosterFollow ·3.7k William WordsworthFollow ·3.7k

William WordsworthFollow ·3.7k Bill GrantFollow ·2k

Bill GrantFollow ·2k Jules VerneFollow ·11.4k

Jules VerneFollow ·11.4k Leslie CarterFollow ·16.1k

Leslie CarterFollow ·16.1k Dennis HayesFollow ·18.9k

Dennis HayesFollow ·18.9k Robert FrostFollow ·19.7k

Robert FrostFollow ·19.7k Ismael HayesFollow ·11.2k

Ismael HayesFollow ·11.2k

Ashton Reed

Ashton ReedUnveiling the Silent Pandemic: Bacterial Infections and...

Bacterial infections represent...

Brent Foster

Brent FosterFinally, Outcome Measurement Strategies Anyone Can...

In today's...

Brett Simmons

Brett SimmonsUnlocking the Secrets to Entrepreneurial Excellence:...

Empowering...

Eugene Powell

Eugene PowellOur Search For Uncle Kev: An Unforgettable Journey...

Prepare to be captivated by...

5 out of 5

| Language | : | English |

| File size | : | 10454 KB |

| Text-to-Speech | : | Enabled |

| Print length | : | 476 pages |